Heating industrial sheds

Industrial sheds have many challenges in terms of heating the environment in a short time and also during the working hours of the shed. The heating of the shed should be in such a way that it lasts in the shed for the longest time with the lowest cost and the highest efficiency. It is possible to maintain the temperature through insulation and isolation of the shed, but it is possible to create this heating by using hot air heaters, hot water boilers and fan coils.

Methods of heating industrial sheds

Heating industrial sheds using hot air heaters

One of the ways is to use hot air heaters that are able to heat the environment and provide heating for the shed by using fuels such as diesel and gas. Heaters should be designed in such a way that they can supply the heating of the shed through ducting in the shortest possible time. By using strong fans, the shed can be heated in a shorter time. In this way, the heat produced will go further and can spread the desired heat in the shed. Of course, strong fans require more heating. In hot air heaters, this requires the existence of several heaters with high flow fans as well as basic ducting.

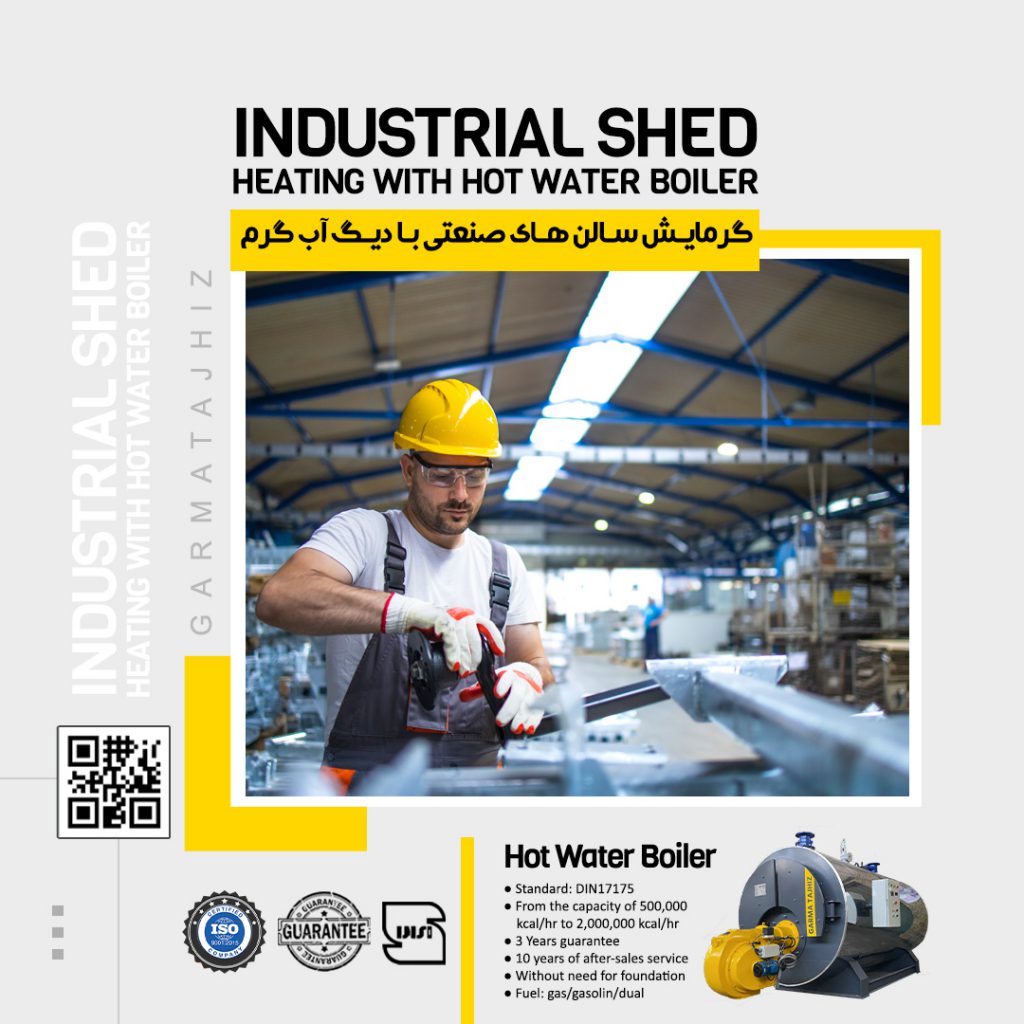

Heating industrial sheds using hot water boilers and fan coils

One of the methods of heating industrial sheds is to use hot water boilers and fan coils or industrial air conditioners to create favorable air. This solution can heat the whole shed by using hot water and using fan coils. This way is placed in a higher position in terms of energy consumption and efficiency. Hot water can heat the shed for a longer period of time and also provide hot water for the employees in addition to heating the shed. Among the other advantages of using hot water, we can mention efficiency and also having hot air during the hours when we are facing a gas or other energy outage. Also, hot water can distribute hot air more evenly in the shed. On the other hand, it is possible to distribute the heat in all parts of the shed by using a hot water boiler in large sheds, especially sheds with a longer length. Also, due to the presence of a separate engine house, hot water boilers can be installed separately from the shed environment and occupy less space. In the summer, the hot water boiler is used only to provide hot water and the fan coils or air conditioners are turned off. Also, in terms of energy consumption and efficiency, superheat boilers have a higher position and are less expensive.

The most important feature of fan coils is that it has a high power in throwing air, which is due to the special fan used in it, and because the height of the roof of the sheds and large sheds. is high, it throws hot air well to the floor of the hall. In addition, if in addition to the heating of the industrial hall, a cooling system is also needed, instead of hot water on hot days of the year, cold water can be flowed in its coils to perform the cooling process. The point is that cold water should be created by the chiller and sent to the unit heaters.

Because the fan coils are inside the shed or shed, they are not able to bring fresh air into the shed

Heating industrial sheds using industrial radiant heater

Radiant heater devices are usually installed on the ceiling and are only responsible for heating large sheds or warehouse heating. If a radiant heater system is used in a shed or shed, a separate system should be considered for supplying and circulating fresh air, for cooling and for regulating air humidity.

This system has disadvantages that can be mentioned as follows:

- Lack of air circulation and fresh air supply

- Failure to adjust air humidity

- Lack of air filtration

- Inability to accurately adjust the temperature

- Higher initial price per heating per square meter of the shed compared to other systems

- There is a risk of fire due to the multiple wirings and vents in each ceiling or wall panel

- Lack of easy access for cleaning, performance checking, periodical inspection and repairs due to installation on the ceiling or high height

In this method, due to the inability to control the ambient temperature and humidity, it is possible to make this system have more control capabilities by using other control equipment.